NCKU’s College of Engineering covers a wide range of fields including aeronautics and astronautics, architecture, civil engineering, hydraulic and ocean engineering. Through the active pursuit of academic excellence and commitment to academic research, it has entered the top 1 per cent of organisations in engineering and material fields around the world. It also entered the top 45 in the World University Ranking for engineering produced by the U.S. News & World Report. In addition, it promotes industry-academy cooperation, forges industry-academy links, assists in upgrading industry research and development, creates industry values and is committed to Taiwan’s development in innovative industries.

Industry 4.1: Intelligent manufacturing with Zero Defects

In response to the Higher Education Sprout Project and Smart Machinery Industry Promotion Programme initiated by the Taiwanese government, Professor Fan-Tien Cheng established the Intelligent Manufacturing Research Center (iMRC) in early 2018. The mission of iMRC is to realise the vision of Industry 4.1, which is to achieve nearly Zero Defects in all products, as defined by Professor Cheng. There are two phases to achieve this goal: Phase 1 accomplishes Zero Defects of all the deliverables; and Phase 2 further ensures Zero Defects of all the products via big data analytics and continual improvement.

iMRC integrates the research energy from different universities and fields to develop the Intelligent Factory Automation (iFA) system platform based on our Advanced Manufacturing Cloud of Things (AMCoT) framework (IEEE CASE 2017 Best Application Paper Award), which can be implemented in various equipment and production lines of manufacturing industries. Intelligent manufacturing services such as Automatic Virtual Metrology (AVM), Intelligent Predictive Maintenance (IPM) and Intelligent Yield Management (IYM) of the iFA system are deployed to exceed Industry 4.0 and achieve the goal of nearly Zero Defects of all the products – the state of Industry 4.1.

The iFA system is composed of the following intelligent modules and services: Cyber Physical Agent (CPA) is a key IoT (internet of things) module to fulfil big data collection and edge computing; AMCoT establishes the cloud-manufacturing infrastructure; AVM accomplishes total quality inspection of workpieces; IPM improves production tools’ availability; and IYM constructs searching infrastructure to identify root-causes of a yield loss. To promote iFA, iMRC along with Chunghwa Telecom, iMSS Ltd and FS-Technology established an Intelligent Manufacturing Solution Strategic Alliance in December 2018 to commercialise the iFA system and launched the server-based and cloud-based iFA services for requirements from different-sized enterprises. Cloud-based iFA offers on-demand monthly subscription, which can save the infrastructural cost and is especially suitable for small and medium-sized enterprises.

The iFA system is composed of the following intelligent modules and services: Cyber Physical Agent (CPA) is a key IoT (internet of things) module to fulfil big data collection and edge computing; AMCoT establishes the cloud-manufacturing infrastructure; AVM accomplishes total quality inspection of workpieces; IPM improves production tools’ availability; and IYM constructs searching infrastructure to identify root-causes of a yield loss. To promote iFA, iMRC along with Chunghwa Telecom, iMSS Ltd and FS-Technology established an Intelligent Manufacturing Solution Strategic Alliance in December 2018 to commercialise the iFA system and launched the server-based and cloud-based iFA services for requirements from different-sized enterprises. Cloud-based iFA offers on-demand monthly subscription, which can save the infrastructural cost and is especially suitable for small and medium-sized enterprises.

With the iFA system, the industrial upgrading can be accelerated, which is beneficial for global economic development. The iFA system was demonstrated on FEMCO Group’s automation wheel machining system at the iMTduo Taipei Nangkang Exhibition Center in May 2018, and displayed again three months later at the Taipei Plas show on ChumPower’s LSS8 blow molding machine. Moreover, the iFA platform has been successfully implemented on production lines of semiconductor manufacturer ASE Group, Aerospace Industrial Development Corporation and chemical enterprise Formosa Plastic Group.

In addition, iMRC focuses on optimising the AMCoT framework. Professor Cheng has hosted the Advanced Manufacturing Technology-Smart Machinery System and Networking integrated project of MOST – “Advanced Manufacturing Cloud of Things Based on Container Technologies” (AMCoTC) – since December 2018, which aims to use new-generation virtualisation technology (e.g, Docker, Kubernates, etc.) to build an intelligent manufacturing information and communication platform, in order to containerise the intelligent services modules.

Given that Addictive Manufacturing (AM) applications are booming in recent years, in order to solve production issues and improve quality, iMRC developed the Intelligent Additive Manufacturing Architecture (IAMA) so as to apply AVM technology and the iFA system into the AM domain. Currently, iMRC is collaborating with the National Institute of Standards and Technology (NIST) in the US with the intention of adding its IAMA research results into NIST’s Additive Manufacturing Materials Database (AMMD).

NCKU alumna becomes first Taiwanese to win Boat International’s Young Designer of the Year Award 2019

Yih-harn Liu, an alumna of NCKU’s Department of Systems and Naval Mechatronic Engineering, entered Boat International’s yacht design competition and won the Young Designer of the Year Award 2019, becoming the first Taiwanese to win a major award in the international yacht community.

Sheng-Chih Shen, chair of the Department of Systems and Naval Mechatronic Engineering, stresses that NCKU offers many opportunities for cross-disciplinary learning. In addition to their engineering education, students at the Department of Systems and Naval Mechatronic Engineering can take classes at the College of Planning and Design if they are interested in design, drawing or aesthetics. For years, there has been no shortage of system and naval mechatronic engineering majors pursuing their master’s in design, and students in the Department of Industrial Design have also taken part in research collaborations with their advisers and professors at the Department of Systems and Naval Mechatronic Engineering.

Furthermore, NCKU has many departments and a diverse selection of clubs to help students cultivate their skills in coordination, problem solving and management, and to expand their social networks. Yih-harn Liu’s achievement is the best example of the advantages offered by NCKU’s diverse learning environment.

|

|

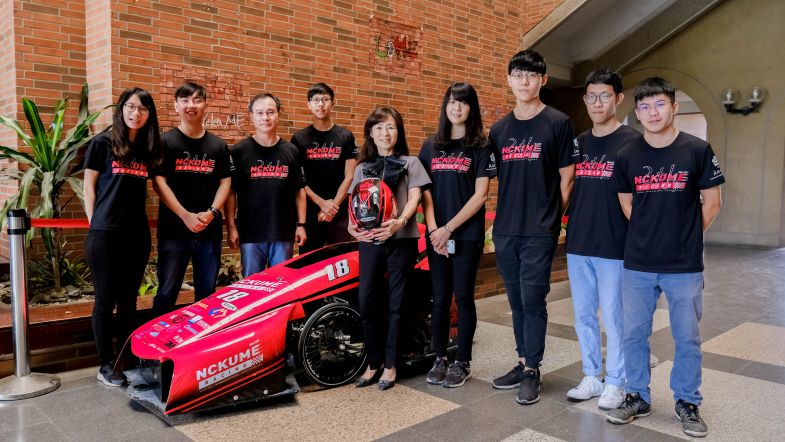

NCKU racing team to present new extreme lightweight racing car

The NCKU Formula Racing Team, established in 2018, consists of a group of college students who are passionate about engineering and use their cross-field knowledge to create top-notch electric racing cars. Their main goal is to represent not only NCKU but also Taiwan in Formula SAE, which is held in Japan every year, and pitch their engineering capabilities against other university students from around the world.

Members of the team devote all their spare time to the design and manufacture of racing cars. It took only a year to build the second Formula Electric racing car in Taiwan that could pass all the static inspections, which include the mechanical and electrical systems. Soon after, in autumn 2019, NCKU Formula Student merged with NCKUME Racing, which was established in 2017. NCKUME Racing had participated in the National Electric Vehicle Innovative Design and Implementation Competition and the National Environmental and Energy-saving Vehicle Competition for two years, and had achieved excellent results.

In the College of Engineering, Formula SAE is seen as a grand, world-class competition. Participants from all over the world gather to show their aptitude in building racing cars. And this, in turn, attracts major automakers from different countries looking to cultivate qualified people to meet their requirements.

From the beginning, the team have positioned themselves as a car factory. Team members deal with challenges from project planning and business analysis, to engineering design and outsourcing manufacturing. Students learn to solve complex issues through cooperation and will make a profound contribution to future industries.

|

|